Why Cryogenic Valves Design For Extended Bonnet

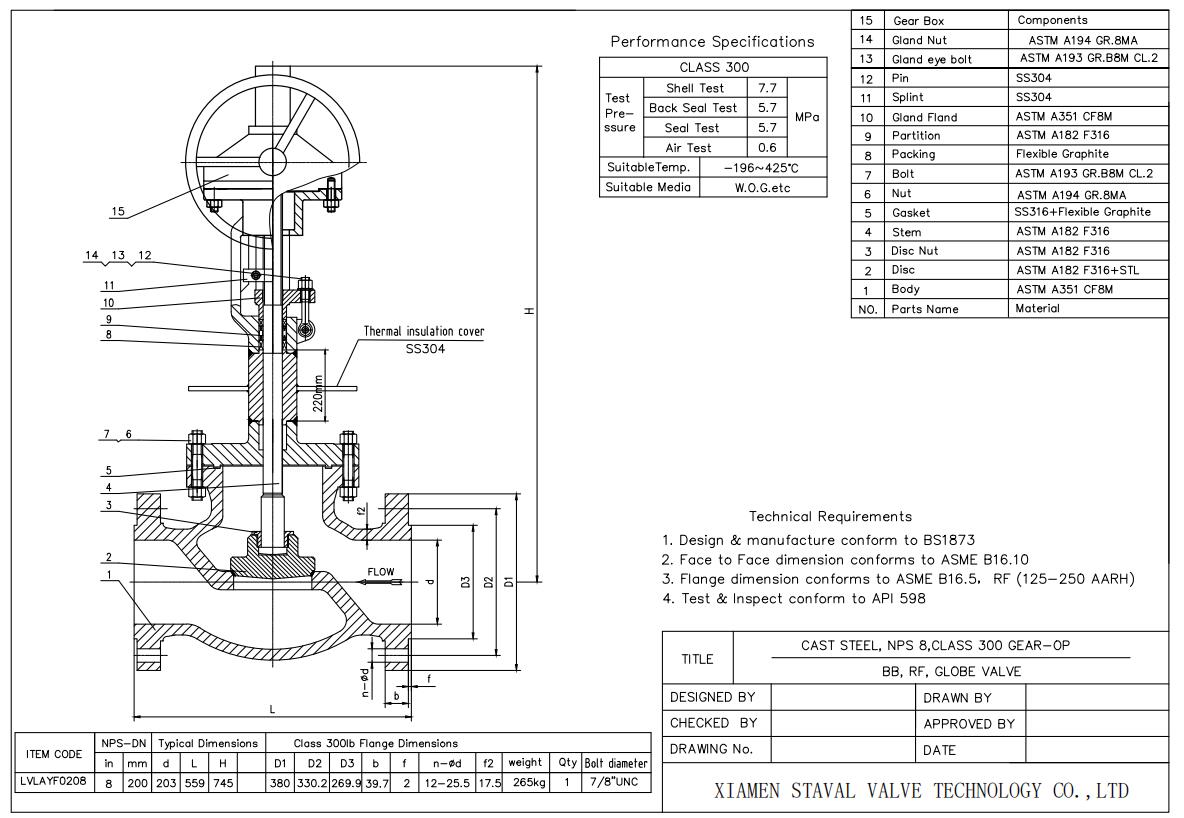

The valve suitable for medium temperature -40℃~-196℃ is called cryogenic valve, and this kind of valve generally adopts extended bonnet.

The extended bonnet is used to specify cryogenic valves including cryogenic emergency shut-off valves, cryogenic stop valves, cryogenic check valves, LNG special cryogenic valves, NG special cryogenic valves, etc., which are mainly used for 300,000 tons of ethylene, liquefied natural gas and other chemical plants. The output liquid cryogenic medium, such as ethylene, liquid oxygen, liquid hydrogen, liquefied natural gas, liquefied petroleum products, etc., is not only inflammable and explosive, but also vaporizes when the temperature rises, and the volume expands hundreds of times when it is vaporized.

The extended bonnet is specified because:

1. The extended bonnet has the function of protecting the stuffing box of the cryogenic valve, because the tightness of the stuffing box is one of the keys to the cryogenic valve. If the stuffing box leaks, it will reduce the cooling effect and cause the liquefied gas to vaporize. In the low temperature state, as the temperature decreases, the elasticity of the packing gradually disappears, and the anti-leakage performance decreases. The leakage of the medium causes the packing and the valve stem to freeze, which affects the normal operation of the valve stem. At the same time, the valve stem will move up and down. The packing is scratched, causing serious leakage. Therefore, it is necessary to ensure that the temperature of the filling part is above 8°C.

2. The extended bonnet structure is convenient to wind the cold insulation material to prevent the cold energy loss of the cryogenic valve.

3. The extended bonnet structure of the cryogenic valve facilitates quick replacement of the valve main part through the bonnet removal. Since the process pipes and valves in the cold section of the equipment are often installed in the 'cold box', the extended bonnet valve cover can extend through the wall of the 'cold box'. When replacing the main part of the valve, only the valve cover is needed for disassembly and replacement, without disassembling the valve body. The valve body and the pipeline are welded into one body, which reduces the leakage of the cold box as much as possible and ensures the sealing of the valve.